Products

Nexl Studio

- Home

- Products

- Nexl Studio

NexlStudio is a GUI-based programming tool that creates and executes dedicated programs. It is a program that can be used by both beginners and experts through free customization and user-friendly visualization. It uses software that has been used and validated for years in various fields and provides a variety of commands based on accumulated data. It also provides a variety of templates to enable rapid development. It provides tools and algorithms specialized in the field of machine vision and supports various hardware required to build inspection systems. Simplify the deployment of complex machine vision systems with a single program.

-

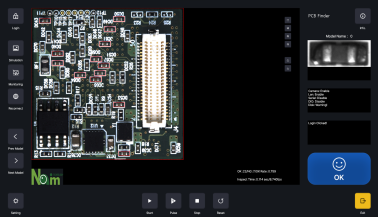

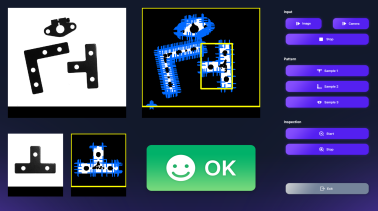

PCB part inspection software

The problem with the component elements on the PCB is not only a defect problem, but also a product quality problem. The visual inspection of PCB parts elements is performed with camera image processing, which is much more precise and convenient. It provides a variety of functions to easily and quickly inspect numerous kinds of PCBs and parts elements.

-

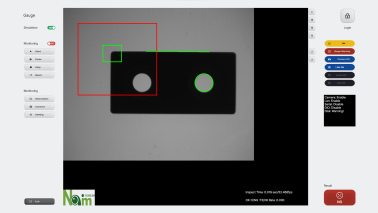

Mold Dimension Measurement Software

We provide a variety of tools needed for dimension measurement. It supports sub-pixeling and can find lines, circles, intersections, etc. Various measurements such as the radius and center coordinates of a circle, the slope of a line, the shortest distance between a point and a line, and the angle between lines are also easily implemented.

-

OCR inspection software

Optical Character Recognition is used to determine part numbers, manufacturing dates, etc. You can use the pre-learning function to accurately determine things like multiple font types, rotation, space recognition, and separation recognition of linked characters.

-

Product classification software

It is possible to find patterns considering changes in rotation and size. It uses a feature-based algorithm and a geometric-based algorithm and is useful for various inspections such as product classification, product existence, and alignment.

-

Intuitive Inspection Commands

The familiar and intuitive commands lends to its user-friendliness.

-

Supports Different User Usage Levels

Depending on the user, functions can be simplified or detailed to enable effective use.

-

Key Inspection Features

It has strong inspection capabilities and various inspection items.

-

Broad Range of Utilization

It can be connected to various hardware and used in various fields of environment.

-

Proposed Stable Inspection Guide

Based on the accumulated inspection data, we propose the best inspection system for immediate application.

- Supports various image preprocessing. (Contrast, Erode, Flip, Gaussian Filter, Sobel, etc.)

- Character recognition. The recognition rate is further improved by using the training function.

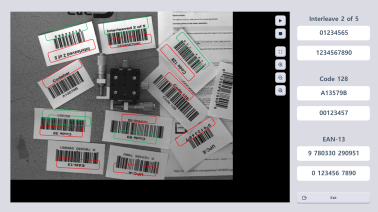

- 1D Barcode (EAN-8, Code 128, Code 39, EAN-13/UPC-A, UPC-E, Interleaved 2 of 5)

- 2D Barcode (QR Code)

- Find Edge, Find Line/Circle, Line Fitting, Circle Fitting

- 3 points angle, 2 line angle, 2 points Distance, etc

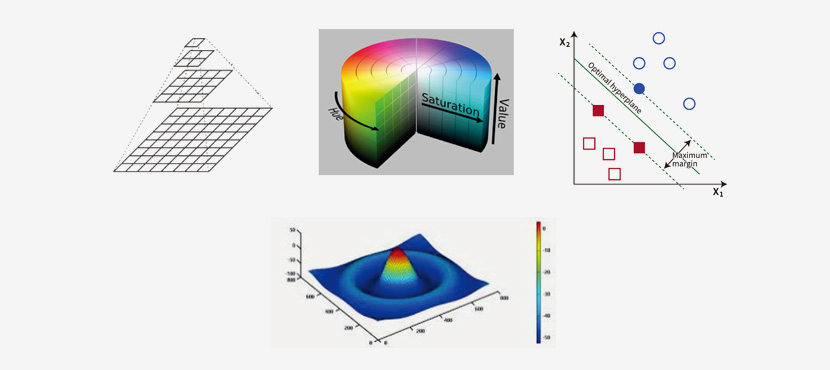

- Blob Analysis, Pattern Matching

- Feature Matching (Shape Matching, ORB, etc)

- Geometric Matching

- Color Inspection

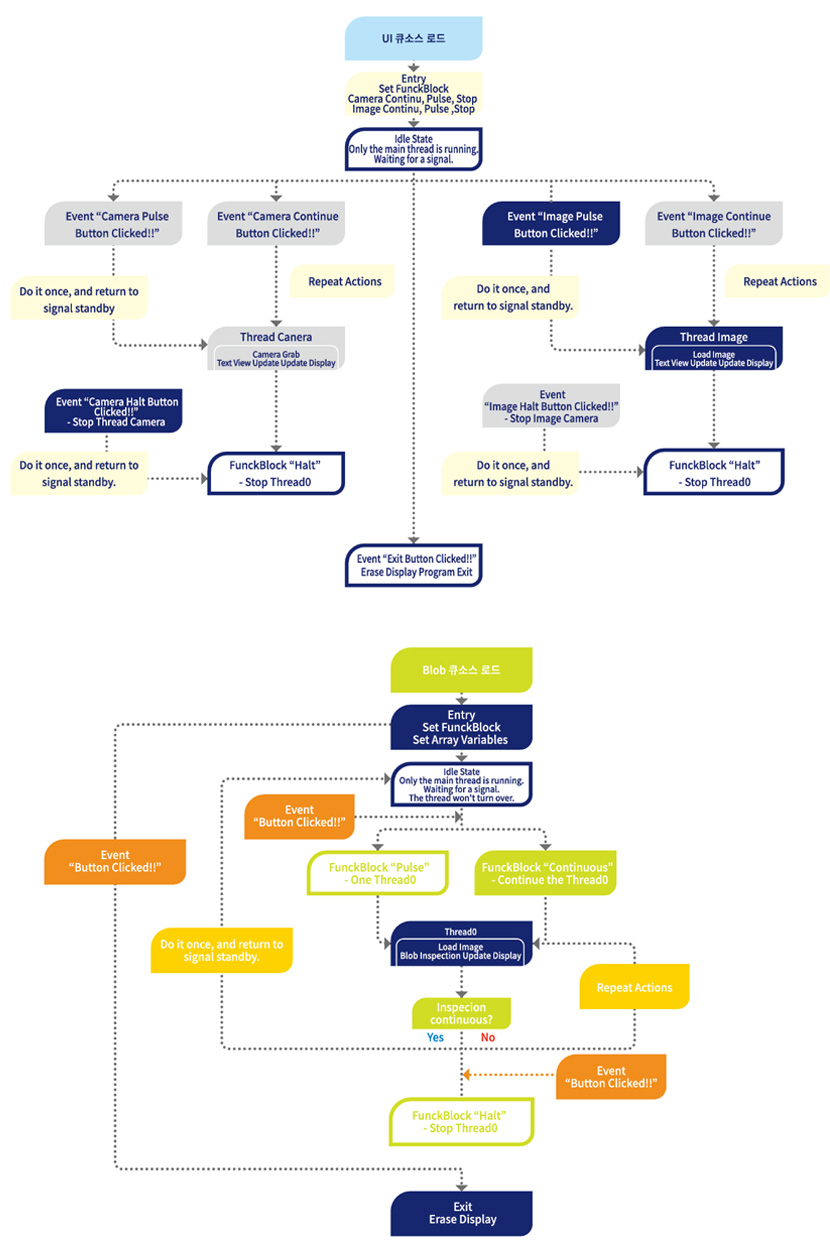

- Creation and modification of commands and data is done through a GUI tool.

- You can design the execution screen in the form the user wants.

- You can create button function blocks to handle events such as clicks.

- You can configure a multi-threading environment by running multiple logics as threads.

- We provide various templates for users who are not familiar with programming.

- Various logic can be configured through control blocks such as IF, FOR, WHILE, etc.

- Seamless data handling is possible through Array, List, etc.

- Multiple commands can be packaged and reused.

- Supports the use of user algorithms.

- Use the camera calibration tool to calibrate distorted images by lenses.

- Use image analysis tools to analyze image processing and changes.

- Record inspection results and manage image storage space.

- Support vision inspection simulation.

- Support user device control.

- Machine Vision Camera Control

- SW Trigger / External Trigger Support

- Light Strobe Control

- Ethernet / Serial Communication

- DIO Communication

- MS Windows 10/11 64bit

- Intel Core i5 and later

- Memory 4GB or more

- HDD 5GB or more free space

- Monitor resolution 1920 x 1080 or greater

E-Mail : sw.service@natimtechnology.com